|

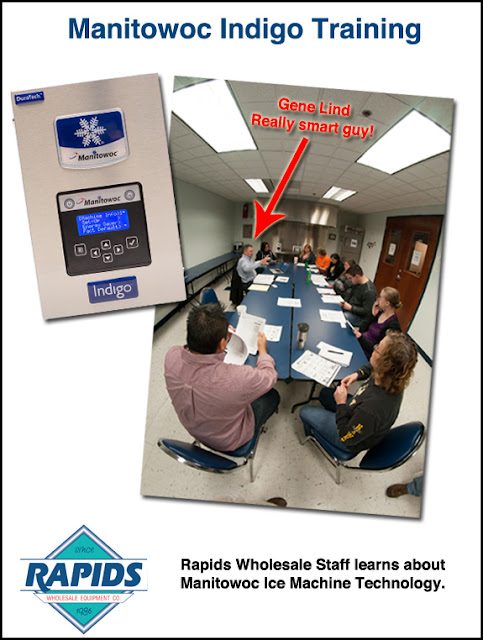

| Manitowoc Training at Rapids Wholesale |

Here at Rapids Wholesale, we had the honor of receiving some sage advice and wisdom from the area's leading authority in all things ice-related, Gene Lind, territory manager for Don Stevens, LLC and an expert in Manitowoc ice makers. Gene walked us through the super cool technology behind the Manitowoc Indigo Series Ice Makers. These commercial ice machines feature LCD displays that will communicate the results of it's intelligent diagnostic monitoring system to you and your staff.

Here is our product spotlight video of the Indigo series ice makers from Manitowoc on our YouTube page.

Check out the highlights of Gene's presentation in this video. Below it, we'll go over some of the key points and tools he's talking about!

These Indigo machines feature a 16-line by 4-line LCD display screen that alerts the user on the condition of the equipment. This gives you the ability to monitor it's status and set reminders for scheduled maintenance and cleaning.

Service Technicians will have the ability to upload machine status to a USB thumb drive for analysis.

The menu is easy to navigate and provides users with pertinent data like machine status as well as serial numbers and production functions. The menu can be displayed in different languages as well.

|

| Manitowoc Indigo Display Demo CLICK HERE! |

For a "live" demonstration of the Indigos menu Navigation CLICK HERE and select the DEMO tab.

Through the menu on the Indigo machines, users get to select the clarity of their ice, also. If you select a clearer cube setting, the machine will cycle and purge more water to obtain a clean, clear cube. This is beneficial to businesses where plating and appearance is very important, and definately useful for those involved in food and beverage photography who prefer shooting natural ingredients.

Indigo machines can be password protected to deter staff and residents or guests from disabling the machine or adjusting the reminders. I can just see it now: the stock boy fiddling with the cleaning schedules to get out of dirty work, ha!

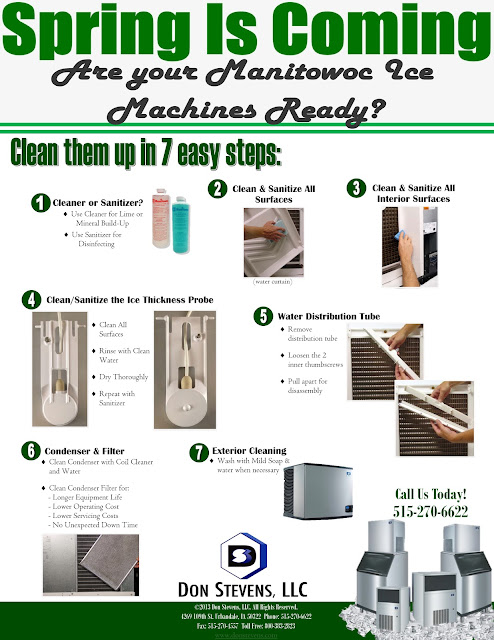

Here is a video that shows how to clean the machines.

Here is a video that shows how to clean the machines.

Indigo machines can be outfitted with the Automatic Cleaning System or AUCS for hands off, pre-programmed cleaning. Cleaner and sanitizer bottles are hooked to the machine, and when it comes time for cleaning, the process is automated. Other reminders can be programmed to alert you when to change the air filter and water filters.

The LuminIce feature is also available on the Indigo line, which prevents yeast and bacterial growth in the food zone of the machines. This is an important feature for any restaraunt or other establishment that has a bakery. LuminIce will keep the unit cleaner for longer periods of time using UV light to kill off bacterial growth.

Another neat feature for lower volume restaurants and especially for hotels and motels is the ability to set a timer for production times. Using the timer will allow you to set the machine to idle production during the overnight hours not to disturb sleeping guests!

To figure out what size machine you will need for your establishment, you can use this handy ICE MACHINE CALCULATOR and then order yours HERE!

Here is a cleaning check list if you already own one!

Here is a cleaning check list if you already own one!

|

| Manitowoc Cleaning Checklist |

Cheers,

Paul

Paul